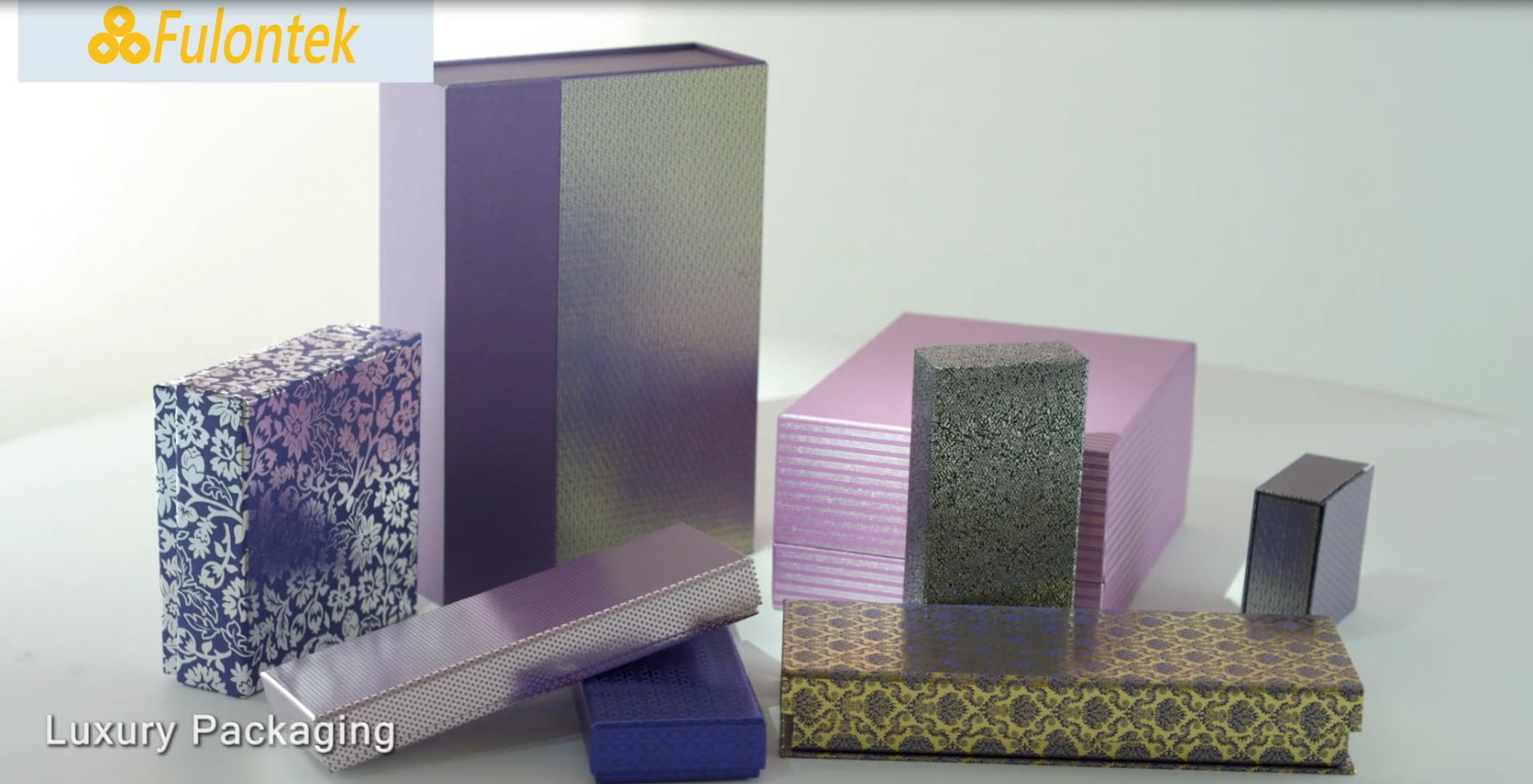

FLHE-1050 AUTOMATIC SHEET TO ROUND PRESSINC HOT STAMPING AND EMBOSSIONG MACHINE

Features

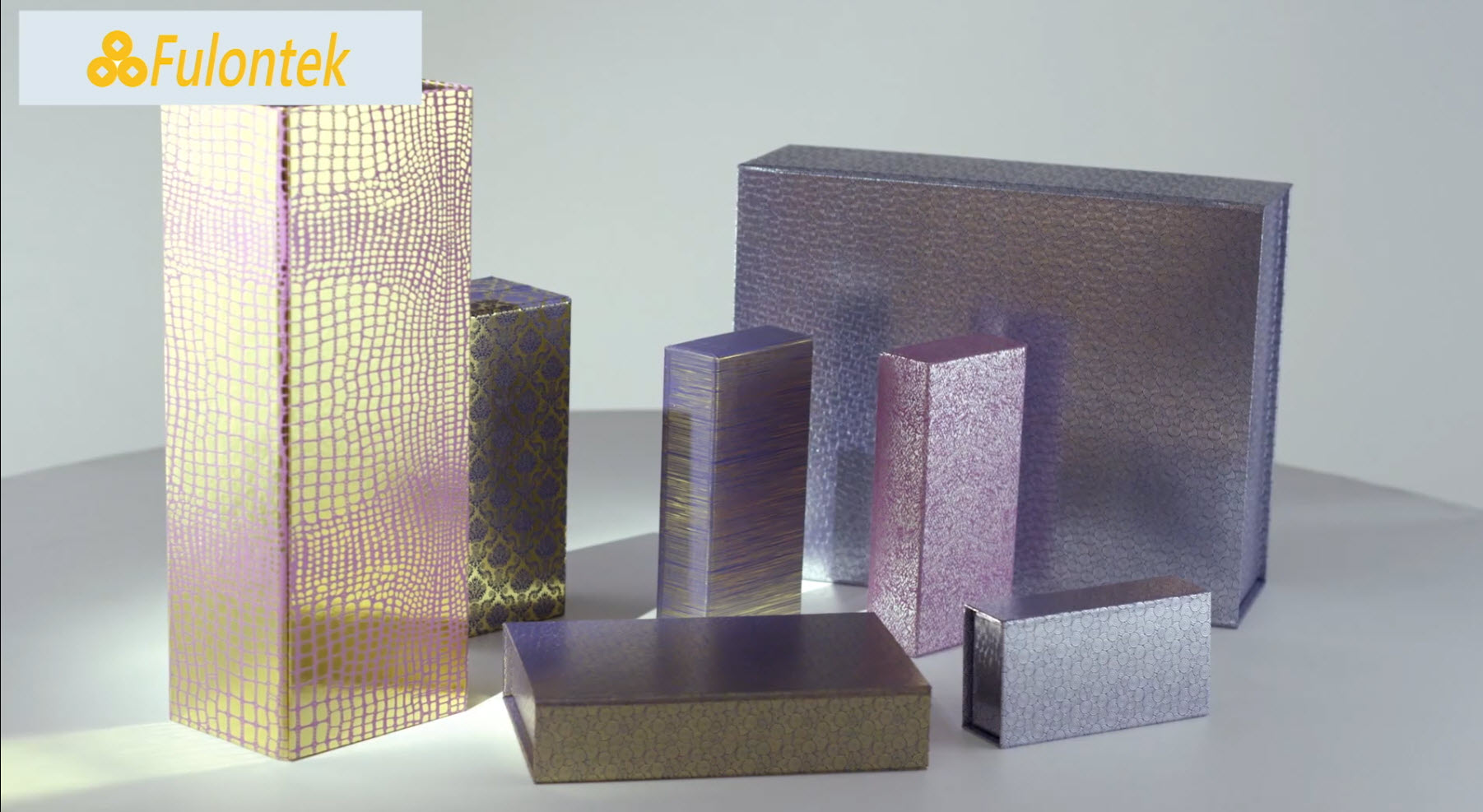

1. Heated by heat transfer oil,the temperature is even and the precision roundness is ideal.

2. The axis of plate roller is equipped with cooling system,that prevents axis from swelling.The axial sleevs is accurately attached with the axis,rendering smooth operation.

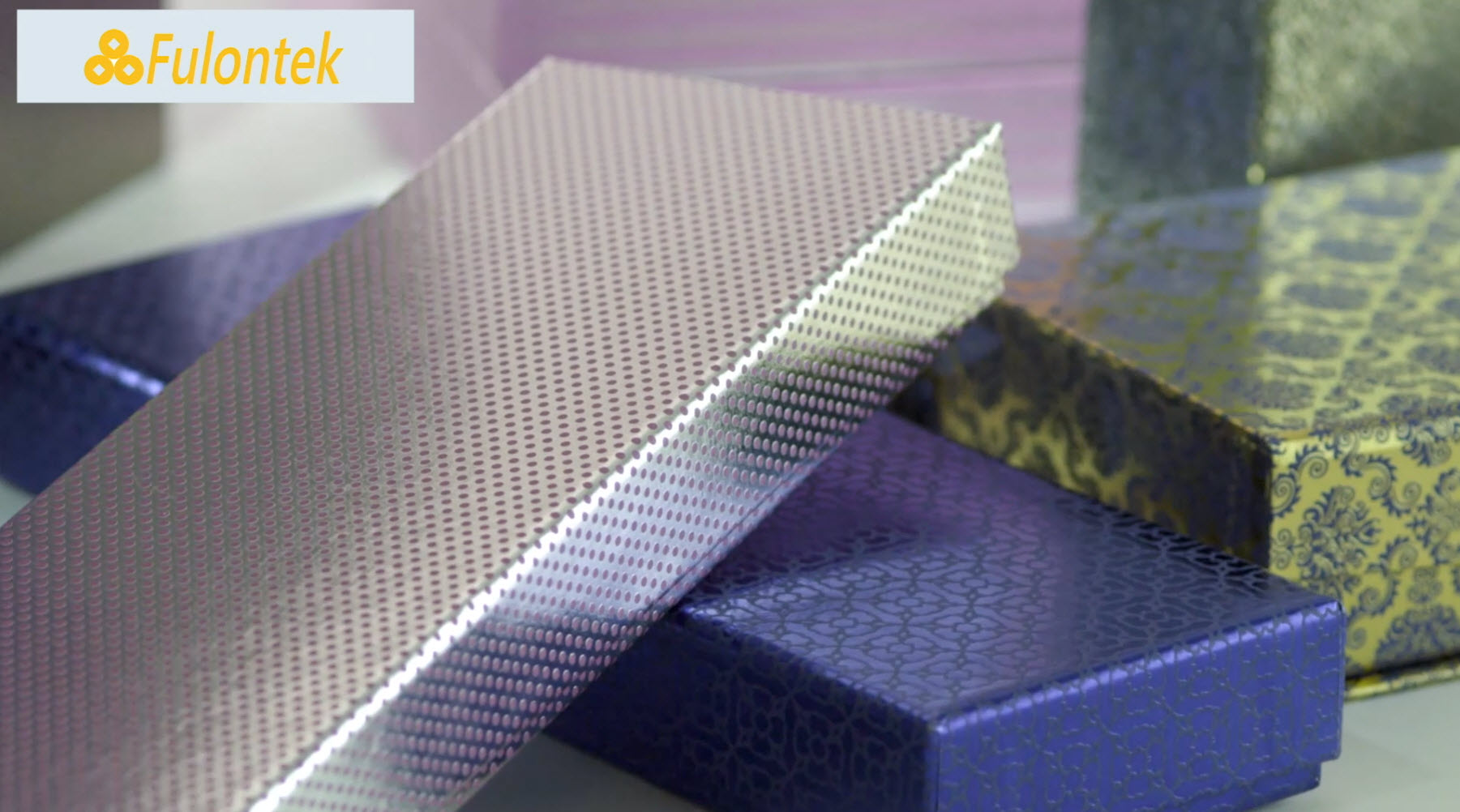

3. Pressurize roller surface is equipped with cooling system:This desing prevents heat transmission from plate roller to the surface of Pressurize roller roller.During machine operation,the temperature of the Pressurize roller is kept as room temperature for the printing of papers and plastics such as PP and PET.With this condition,there won’t be deformation after embossing and hot stamping,and the processing afterward will be smoother.

4. Embossing plate:Made of stainless steel.

5. Hot stamping plate:Stainless plate,Hot stamping without plate:UV oil,or toner.

6. Hot stamping without plate:

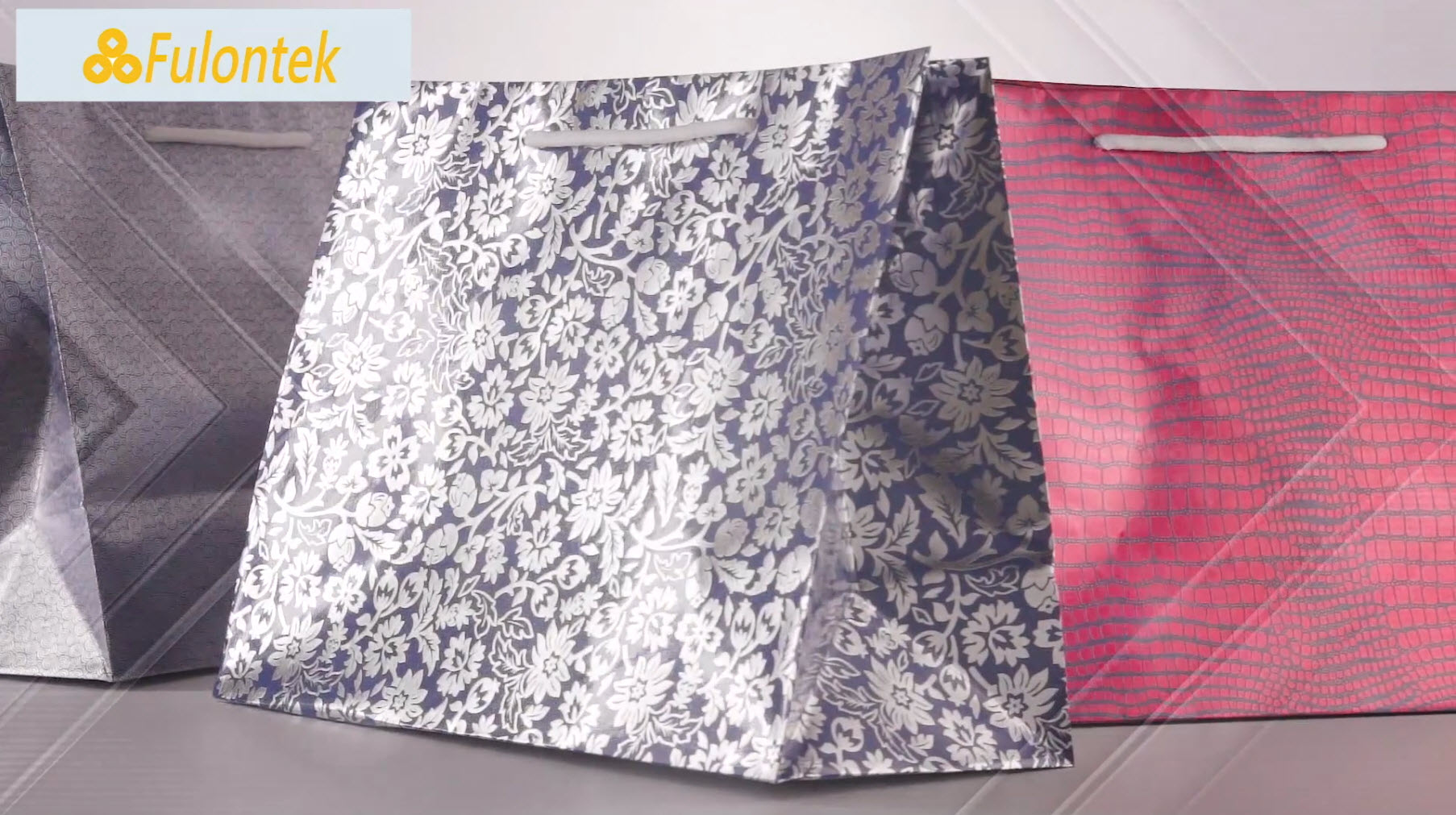

a. Add UV oil onto screen printing device and print on paper,and then proceed hot stamping of the paper.

b. Spraying toner onto paper and proceed hot stamping onto paper.This method makes better quality compared with stainless steel plate hot stamping.

7. Hot stamping after printing:This machine can proceed printing after hot stamping procedure,such as coated paper,clay coated paper,and card paper.

8. Huge area hot stamping:This machine can proceed hot stamping with greater area without making bubbles.

9. Expand roller center is located at the center of the stamping pattern,and there are scale icons at the axis center.All the expanding rollers of the same axis are at the same location so that the location of stamping membrane will be the same.

10.Patented products.SPECIAL DESIGN:

DATA | Model:FLHE-1050 |

Embossing、Hot Stamping area | 1020mmx720mm |

Embossing、Hot Stamping Plate size | 1020mmx835mm |

Max.Paper Size | 1050mmx750mm |

Min.Paper Size | 400mmx300mm |

Processed Thickness | 0.07~0.8mm |

Embossing Job Capacity/Hour | 1,200~2,100 sheets/hour |

Hot Stamping Job Capacity/Hour | 2,400~30,00 sheets/hour |

Foil Film Feed Device(Motor) | 3 sets |

Embossing 、Hot stamping Pressure line | 12~19、6~8 |

Power Required | 51KW |

Air Required | 8kgf/cm²(114psi),720 l/min |

Power Supply | AC 3Phase 220v,380v,400v (depend on local area) |

Net Weight | 8,500.Kgs |

Machine Dimension | 7000x3600x3900mm |