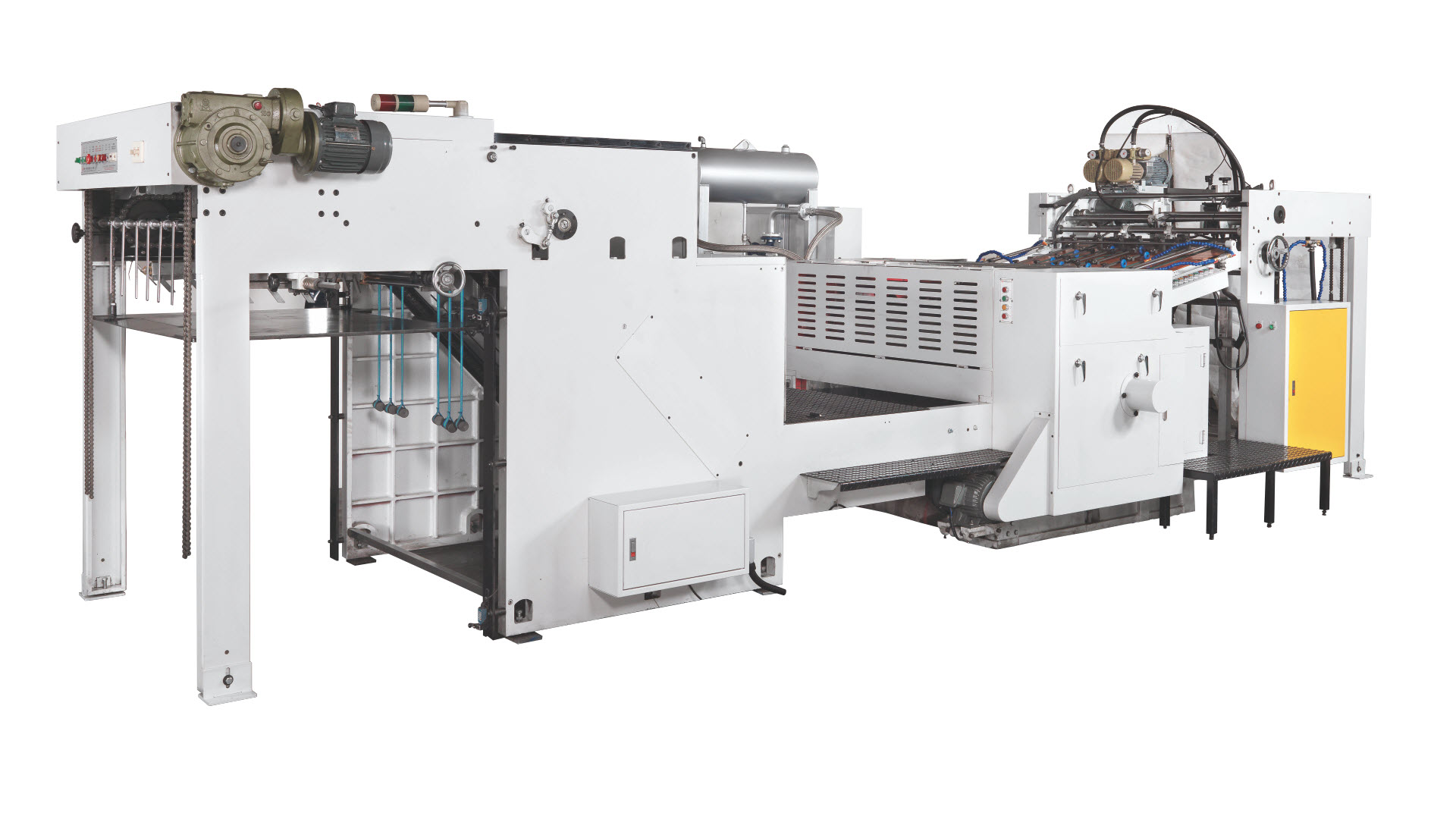

AUTOMATIC SHEET TO ROUND PRESSINC EMBOSSIONG MACHINE

Features

1.Embossing by heating;patterns are transferred by steel plates,saving consumptive and allowing fast development of new products.

2.Cylinder heating with Heat transfer oil:fast and even in temperature.

3.The cooling system can coll off the shaft core of the plata roll pressure roll,in order to have normal operation.

4.The cooling system on the surface of the pressure roll can make the embossing pattern on the same level.Therefore it will not affect the surface when embossing oh plastic material.

5.This unit is capable of embossing on many kinds of paper and various plastic boards.

6.Patenter product.

SPECIAL DESIGN:

| DATA | Model:FLE-1050 | Model:FLE-1280 |

| Embossing area | 1020mmx720mm | 1250mmx900mm |

| Embossing Plate size | 1020mmx835mm | 1285mmx1010mm |

| Max.Paper Size | 1050mmx750mm | 1280mmx930mm |

| Min.Paper Size | 400mmx300mm | 400mmx300mm |

| Processed Thickness | 0.07~0.8mm | 0.07~0.8mm |

| Embossing Job Capacity/Hour | 1,200~2,100 sheets/hour | 1,200~2,100 sheets/hour |

| Embossing Pressure line | 12~19 | 12~19 |

| Power Required | 40KW | 40KW |

| Air Required | 8kgf/cm²(114psi),720 l/min | 8kgf/cm²(114psi),720 l/min |

| Power Supply | AC 3Phase 220v,380v,400v (depend on local area) | AC 3Phase 220v,380v,400v (depend on local area) |

| Net Weight | 6,500.Kgs | 7,500.Kgs |

| Machine Dimension | 6240x2320x2110mm | 6240x25450x2110mm |