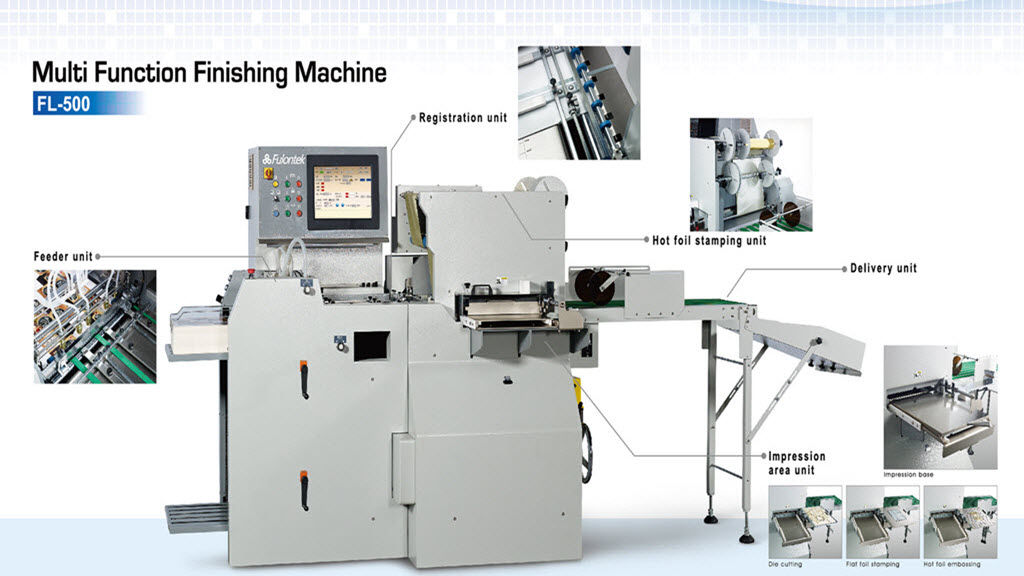

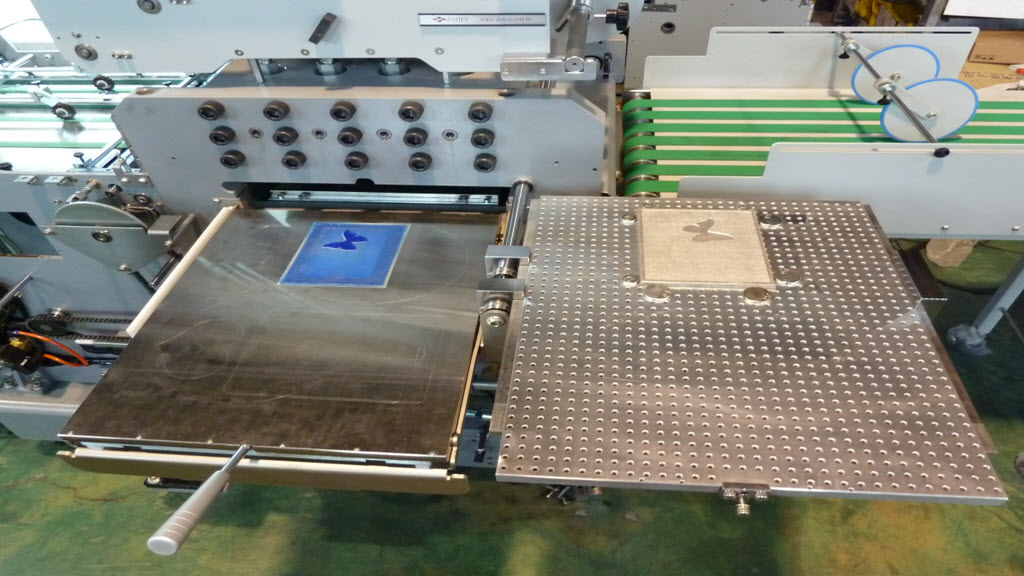

FL-500 MULTI FUNCTION FINISHING MACHINE

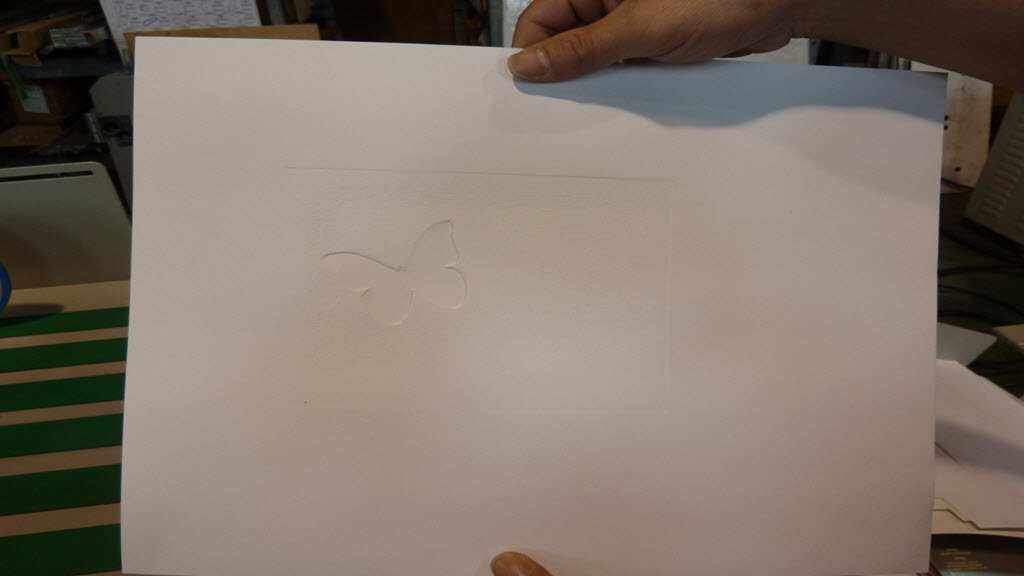

Die cutting, Kiss cutting, Creasing perforating, Blind and foil embossing, Scoring and Imprinting, Hot foil stamping, QFF(quickly foil fusing)

Multi Function Design

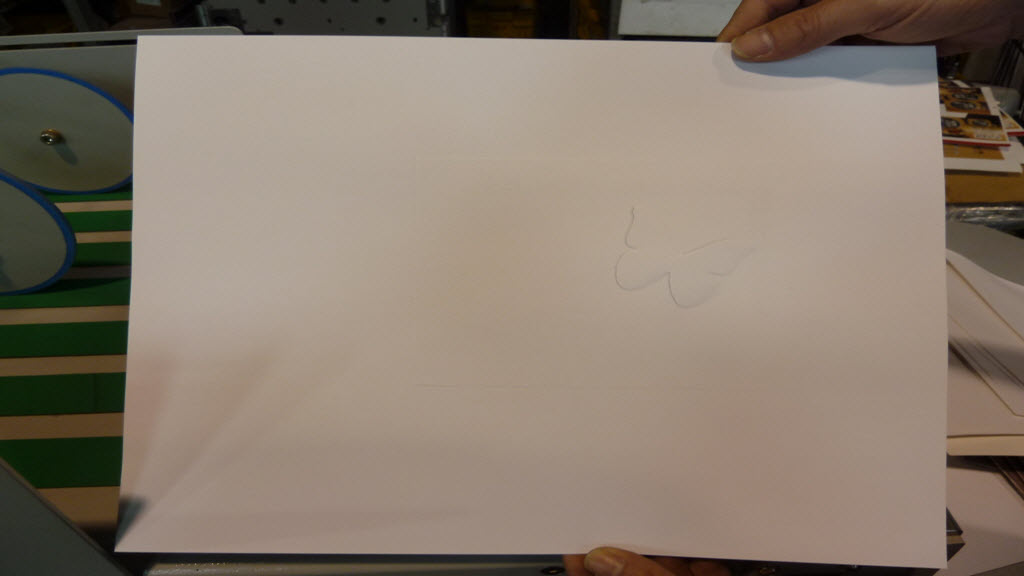

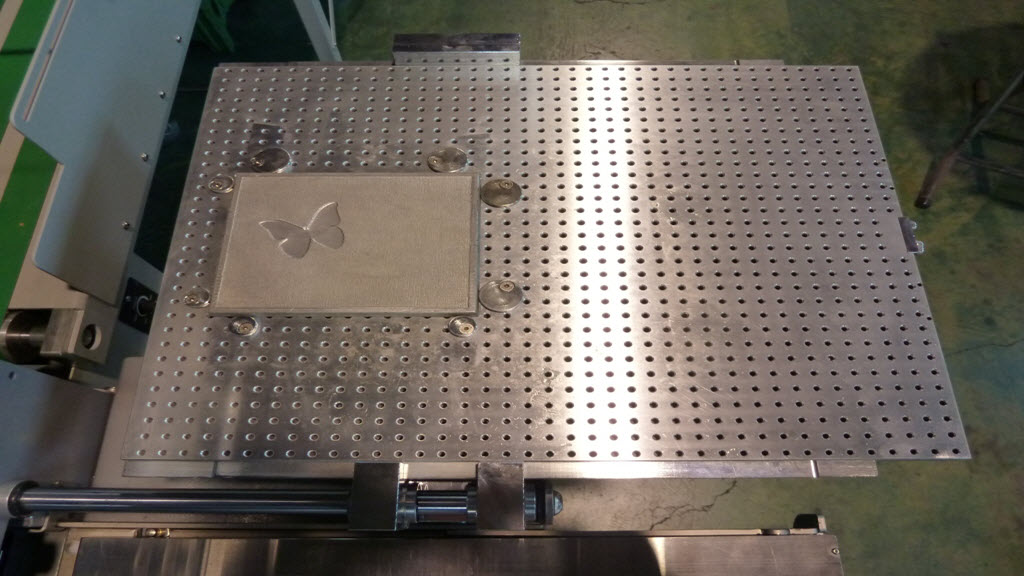

FL-500 capabilities include die cutting, kiss cutting, creasing, perforating, hot foil stamping, blind and foil embossing, scoring, imprinting and HSFF(heigh speed foil fusing), and process one sheet to die cutting, can continue 10 times (max.) to cut, only use same cut blade model. Save the blade model fee.

Quality And Safety

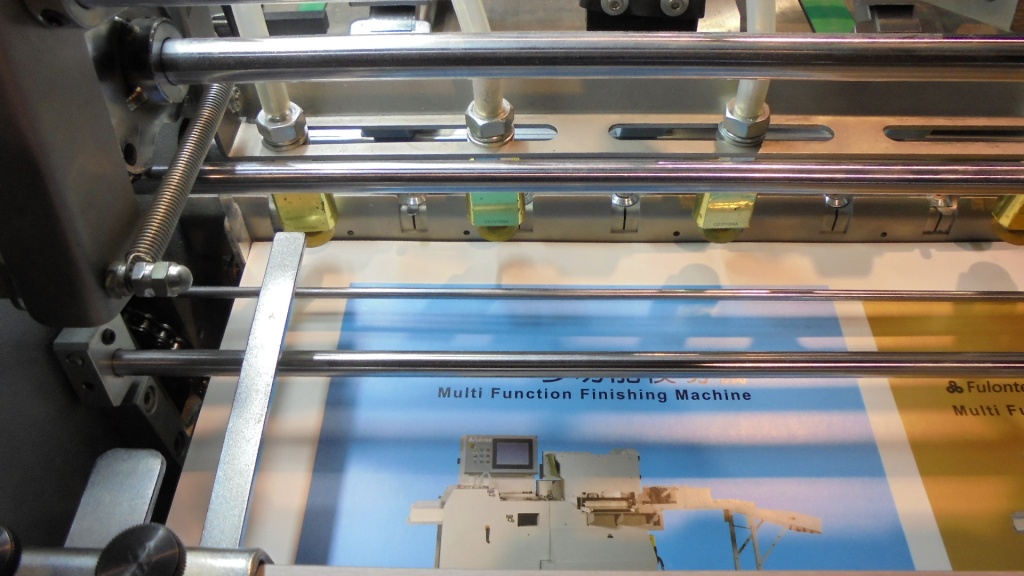

FL-500 multi function finishing machine fufil all international safety standards and are quickly ready for operation. A touch panel with pictogram control makes it very easy to operate, Paper registration foil draw length, counter functions, jam detect/interrupt, double feed detect, speed and impression pressure functions are controlled and displayed through the computer touch screen.

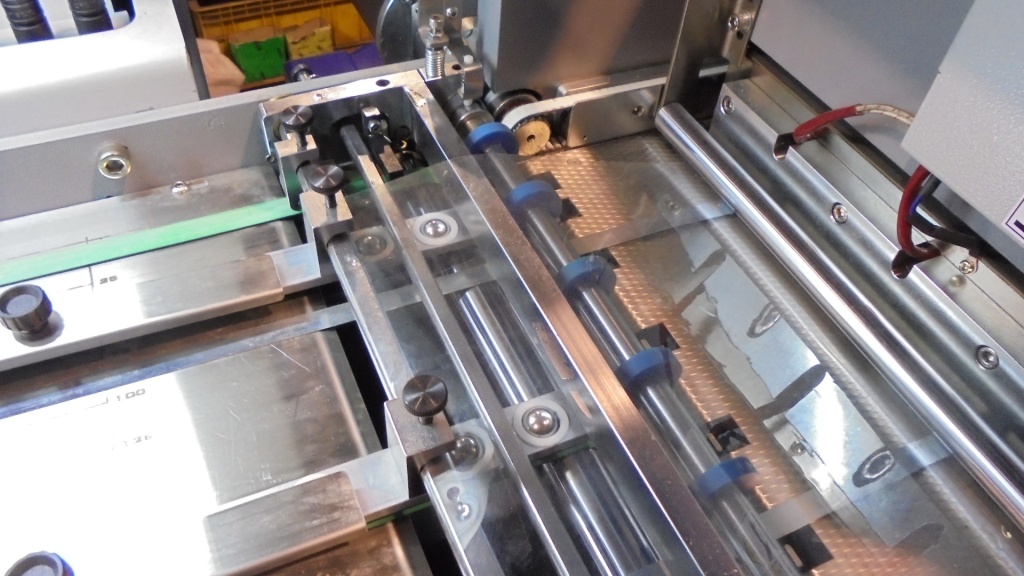

Job set-up at quickly

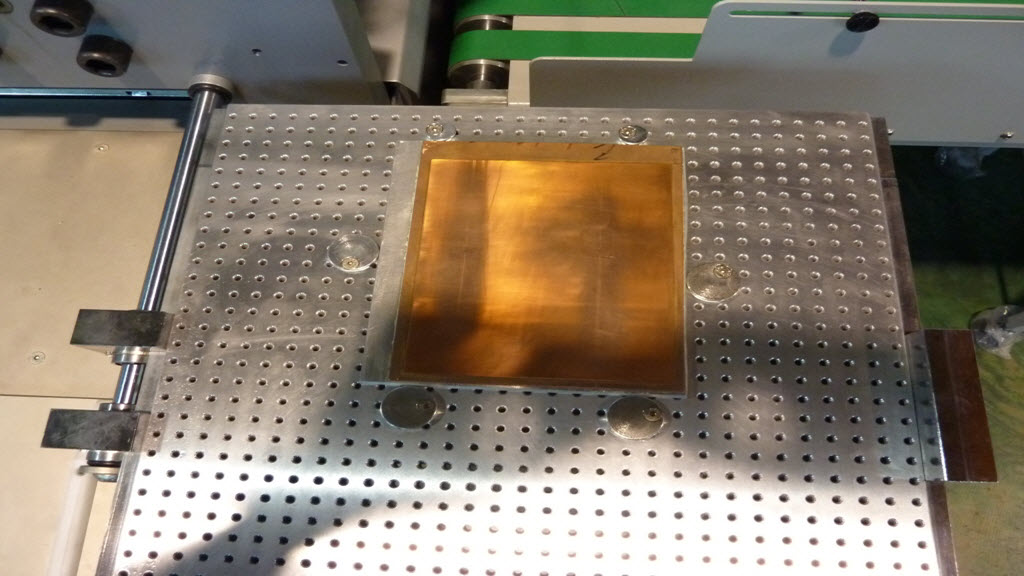

Changeover from hot foil stamping to cutting is done in a jiffy with the FL-500. It takes less than 10 minutes to replace the portable heating plate with it’s insulated frame for a standard chase. You can start cutting or creasing the next job immediately without waiting for cool-down-at a continuously 100% high register accuracy (±0.1mm)

FL-500 system

The FL-500 is designed arround a windows based computer core with a full color display and touch screen (15”) interface.

The headstop paper sensor also confirms each sheet is ready to advance into the impression area, If a skip feed condition occurs, the FL-500 will automatically drop off impression. When the next sheet is detected at the headstop, the machine will automatically returm to the “ON”impression position. The FL-500 will not stop if a skip sheet error occurs.

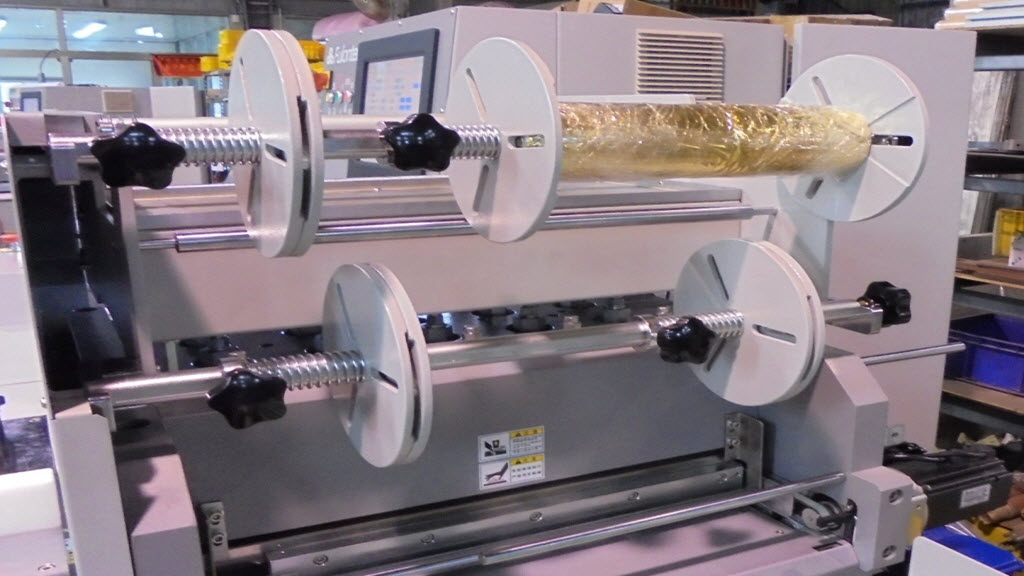

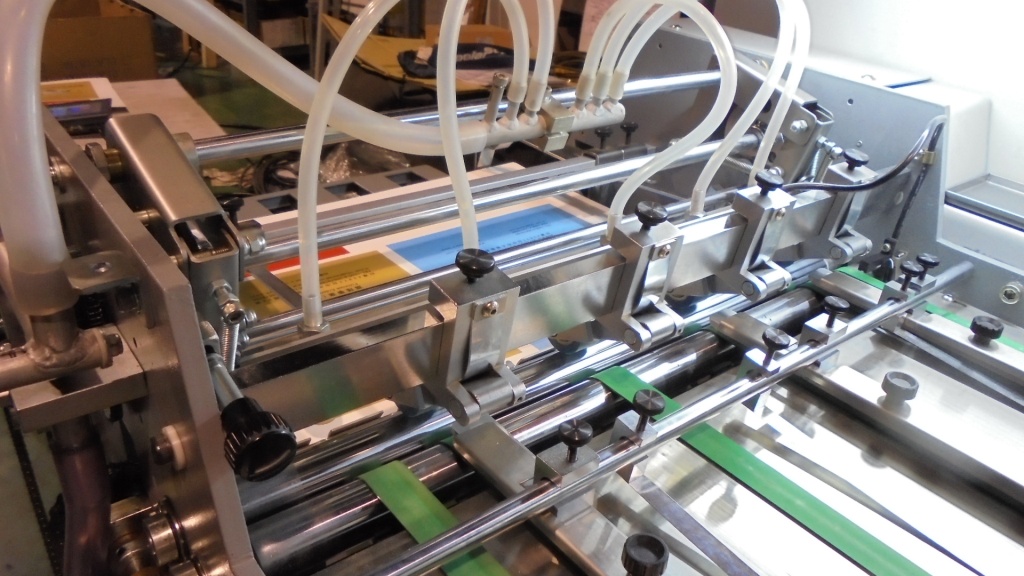

Hot foil stamping system

The standard FL-500 foil system includes dual foil support shafts, dual programmable foil draws, and four foil rewind shafts, multiple foil draw lengths can be programmed to minimize foil waste, up to 182.8㎜ diameter foil rolls can be used and foil draw length can be adjusted while the machine is running.

Jobs

FL-500 applications include greeting cards, business cards, stationery, invitations and announcements, commercial letterpress work as well as die cutting and enhancing digital output.

Using the FL-500, customers can efficiently produce work at speeds up to 6000 sheets per hour.

MACHINE SPECIFICATION

MULTI FUNCTION FINISHING MACHINE

Max. sheet size 520x600㎜(20.47x23.62in)

Min. sheet size 90x90㎜(3.54x3.54in)

Processed materials 0.1∼1㎜

Max. cutting size 500x380㎜(19.69x14.96in)

Min. gripper margin 10㎜(0.4in)

Max. cutting force 40 tonnes

Max. machine performance* 6000 sheets/h

One sheet multi die cutting max.10 times

Main motor 4 kw(5hp)

Vacuum pump 1.3kw(2hp)

Power supply AC 3 Phase 220V,380V,400V

Power requirement 8.5kw

Machine net weight 2900㎏

*dependent on material, application sheet size and die configuration.

Specification could be changed for improvement without prior notice.